5 3

Kumpulan Fima Berhad (11817-V) •

Annual Report 2018

SUSTAINABILITY REPORT 2018

Waste Management

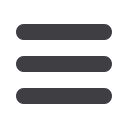

The

Plantation Division

adheres to a

“zero discharge” policy by recycling

waste and by-products. At our palm

oil mill in Indonesia, oil mill waste

comprises of POME and EFB. These are

both utilised in different ways:

POME discharged from the mill must not

be reintroduced into the environment

in its raw form. Raw POME has a high

acid content and, due to its rich nutrient

content, the Biological Oxygen Demand

(“BOD”) level is high too. However, our

average BOD reading for POME during

the land application stage falls well

within the allowable discharge limits of

<5,000 parts per million (“ppm”).

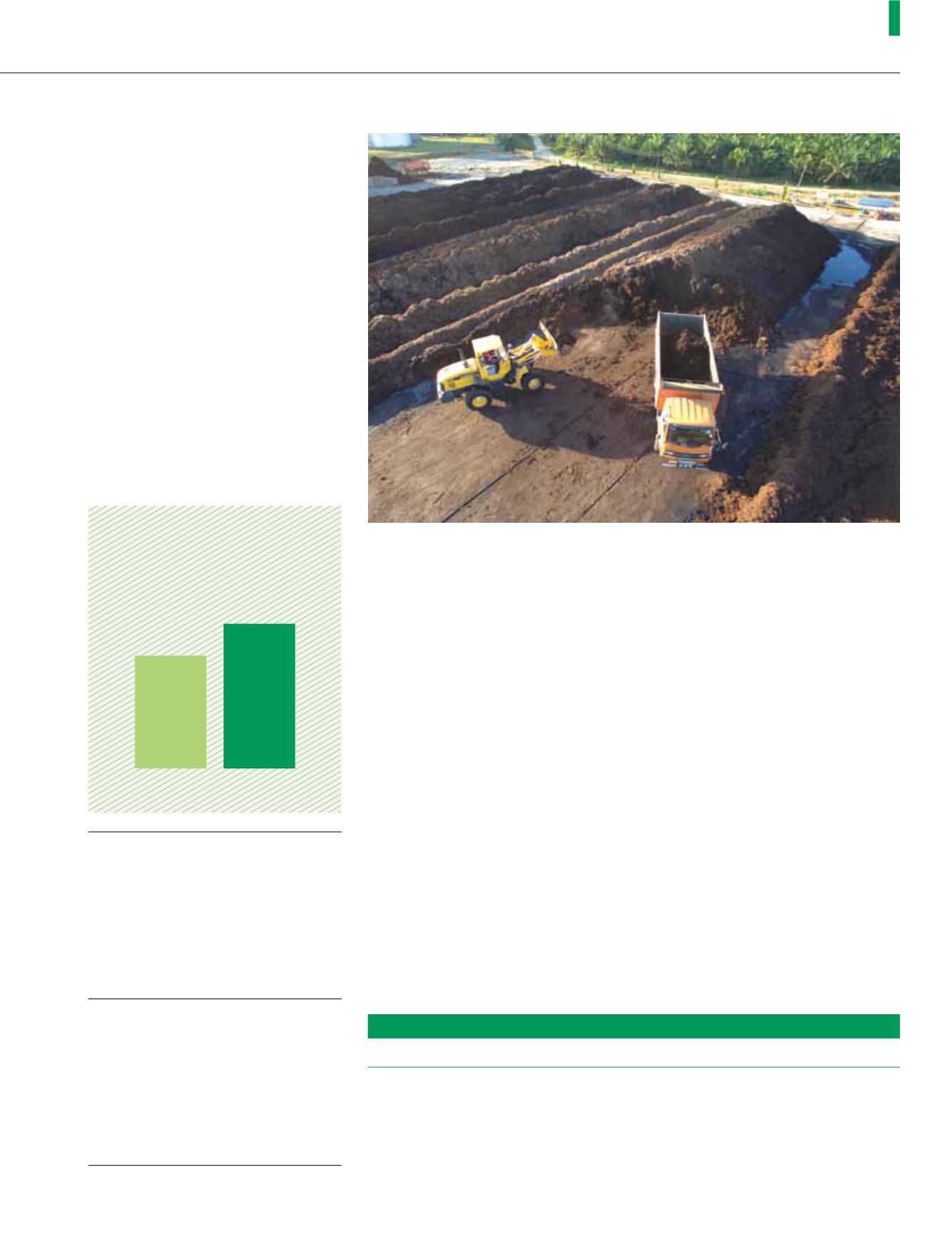

total EFB produced

(MT)

40,332

2017

51,684

2018

91,209

MT

of POME applied to

estate fields in FYE2018

26,395

MT

of EFB processed into

compost in FYE2018

The POME collected from the mill is treated in open anaerobic ponds located on

site. The organic material in wastewater is broken down by natural occurrences of

anaerobic and aerobic bacteria. This process eliminates the need to add chemicals

before the water is discharged and results in successful fish breeding at the final

effluent pond. POME is utilised in two ways. It is either mixed with shredded EFB to

make our compost or applied directly to estate via the furrow system.

In addition to being converted into compost, shredded EFB is also widely used as

feedstock for the steam boiler at the mill for power generation

Further, we regularly monitor the POME used for land application to ensure that it

does not overflow into the natural waterways.

PTNJL has achieved the Green rating, the second highest level in Indonesia’s Program

for Pollution Control, Evaluation, and Rating (“PROPER”) in the manufacturing/

agroindustry category for 4 consecutive years. The Green rating is awarded to

businesses/activities that have displayed environmental management effort and

achieved results better than those required by regulation.

A substantial amount of unused fish parts generated by fish processing activities

at International Food Corporation Ltd (“IFC”), the

Food Division

’s processing plant

in Papua New Guinea, are converted into fishmeal which is then sold to companies

involved in the aquaculture and livestock industries. The remainder is sold to external

fishmeal processors.

FYE2017

FYE2018

Fishmeal

315,000 kg

611,500 kg

Hazardous waste and residual products recovered from our operations are disposed

of in accordance with stringent industry standards and statutory requirements.