5 4

Sustainability report

Waste Disposal by Type

Volume (tonnes)

FYE2017 FYE2018

Scheduled Waste:

Ink containers

3.70

3.58

Contaminated rags

2.90

3.11

Printing ink waste

5.40

3.58

Recycle used oil

15.64

34.05

Solid Waste:

Shredded paper

242.20

209.53

Used Tyres

-

6.00

Scrap Crushed Iron

-

6.00

Food Waste (Head Office)

-

2.53

Plastic (Head Office)

-

0.39

Total

269.84

268.77

Water Management

The Group’s businesses remain focused on efficient water

management through, inter alia, reusing water throughout

their operations and rainwater harvesting.

Food Division

’s

PNG subsidiary, IFC is continuing their efforts to identify

opportunities to reduce their water consumption using a variety

of approaches including water recycling, replacing faulty

equipment, and fixing leakages. In addition, the

Plantation

Division

has installed rainwater tanks at the workers’ quarters

in our Miri and PTNJL estates. This allows us to harvest

rainwater to be used for daily consumption. Weirs have also

been constructed across the field drains at our Miri estate to

facilitate water retention and maintain the groundwater table

at optimal levels.

During the year, water consumption of PTNJL’s palm oil mill

in Sei-Manggaris has increased by 19% compared to last

year, largely as a result of the increase in the volume of crops

processed during the year.

PTNJL has also set aside areas within its plantation as water

catchment zone. Chemical applications are strictly prohibited

at the water catchment zone to facilitate natural re-vegetation

of the area and preservation thereof.

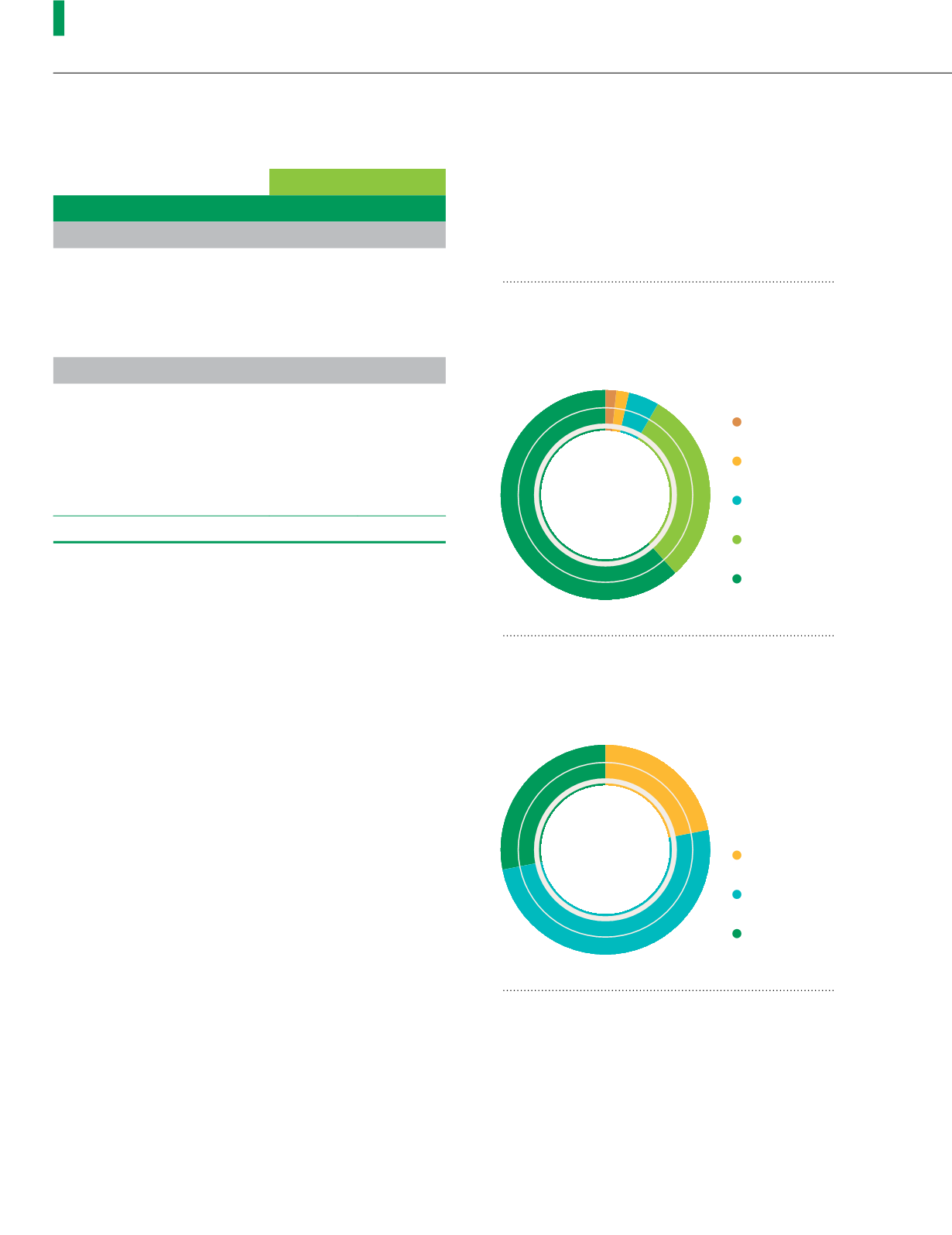

Breakdown of water consumption

by division (m

3

)

Manufacturing

15,391

(2.1%)

Head Office

12,511

(1.7%)

Bulking

33,666

(4.6%)

Plantation

451,798

(61.5%)

Food

221,066

(30.1%)

Breakdown of water usage

by mill (m

3

)

Domestic

86,792.2

(22%)

Processing

110,462.8

(28%)

Boiler

197,255

(50%)

394,510

m

3

of water consumption by mill in FYE2018

(FYE2017: 331,172 m

3

)

734,432

m

3

Total water consumed by the Group

Water consumption

SUSTAINABILITY REPORT 2018