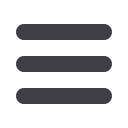

Total Energy Consumption (TJ)

264.44

Terajoule

Total energy consumed by the

Group

(FYE2018: 142.73 Terajoule)

In PNG, the

Food Division

’s energy saving initiatives

include a capex to purchase a new 10 tonnes/hr boiler

and refurbish an existing boiler. The new boiler is fitted

with an economizer which over time, could potentially

reduce the amount of energy that is required to

heat the boiler feed water to operating temperature.

Meanwhile, the refurbishment of an existing boiler

which was undertaken by way of a major overhaul and

descaling treatment have also resulted in improved

heat efficiency. Other initiatives include the recycling of

steam produced by its boilers. This steam energy which

would otherwise be wasted is captured and reused to

supply heat for the heating process.

Since 2011, all biomass residue from our palm oil

mill in Indonesia is either converted into fertiliser/

compost or clean energy. In the case of the latter,

mesocarp fiber, palm shell and shredded EFB are

utilised as feedstock for the steam boiler and the steam

generated therefrom will then fuel the steam turbine

in the cogeneration plant. The impact of the utilization

of biomass as renewable energy has been significant.

Bulking

Plantation

Food

Manufacturing

Head Office

98.33

85.79

63.86

10.12

6.34

Note: “Head office” energy consumption includes the entire building’s

tenants

Total Group co

2

eq

(Scope 1)

Total Group co

2

eq

(Scope 2)

FYE2019

FYE2019

FYE2018

FYE2018

63,297.2

8,003.2

62,398.0

8,141.0

86% of the electricity and heat energy generated

from the cogeneration plant is used to power the oil

mill’s operations. The excess energy is used to power

worker’s quarters, government facilities, schools and

mosque. In FYE2019, 6,216,230 kWh of electricity was

generated (FYE2018: 6,571,920 kWh).

Emission

W

e emit GHG both directly and indirectly. Our

largest impact in terms of emissions is direct

(scope 1) emissions mainly from our businesses’

use of petrol, gas and diesel. Our main source of

indirect (scope 2) emissions is electricity used in our

manufacturing and processing operations.

Overall the Group’s total

emission was higher in

FYE2018 by 1.1% mainly

due to the

Plantation

Division

’s land

development activities

of new estates that took

place.

44

Kumpulan Fima Berhad

(11817-V)

SUSTAINABILITY Report 2019