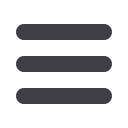

Breakdown of Water Usage by Mill (m

3

)

Boiler

Processing

Domestic*

384,222.00

m

3

of water consumption by mill in FYE2019

(FYE2018: 394,510.00 m

3

)

Domestic*: This includes usage from the rest house, canteen,

mill (non-operational), main office and worker’s quarters

During the year, water consumption of PTNJL’s palm

oil mill has decreased by 2.6% in total compared to last

year, largely as a result of the decrease in domestic

usage (6.1%).

PTNJL has also set aside areas within its plantation

as water catchment zone. Chemical applications

are strictly prohibited at the water catchment zone

to facilitate natural re-vegetation of the area and

preservation thereof.

Energy Management

D

ifferent businesses have quite different energy use profiles and scale. For example,

Manufacturing

operations

source much of their energy from electricity whereas

Food Division

relies heavily on diesel consumption.

Recognising that one size does not fit all, the Group’s Engineering team has been and continues to identify,

test and refine methods and look for opportunities, however small the scale, to reduce the Group’s energy usage.

For instance, replacement of less efficient lightings and HVAC maintenance and optimisation completed during

FYE2019 for the Group’s headquarters in Kuala Lumpur will reap an estimated energy savings of 236,400 kWh per

year. This is equivalent to the average annual electricity used by 29 households*. There are plans to expand the use

of solar energy at the Group’s oil palm plantations in this current financial year.

* Source: US EPA calculator

Improving our energy efficiency not only reduces the use of natural resources and emissions of CO₂ and other

pollutants but also potentially lowers costs.

Division

Diesel

(L)

Petrol

(L)

Fuel Oil

(L)

Grid Electricity

(kWh)

Solar

(kWh)

Bulking

280,401.47

6,006.52 2,046,386.00 1,684,584.09

-

Food

1,353,273.93

6,680.00

-

3,164,951.31

-

Manufacturing

6,513.39

1,100.54

-

2,731,166.45

-

Plantation

2,124,311.04

92,716.53

-

171,053.41

-

Head Office

-

20,446.88

-

1,532,768.59

34,951.75

Grand Total

3,764,498.83

126,946.46 2,046,386.00 9,284,522.86

34,951.75

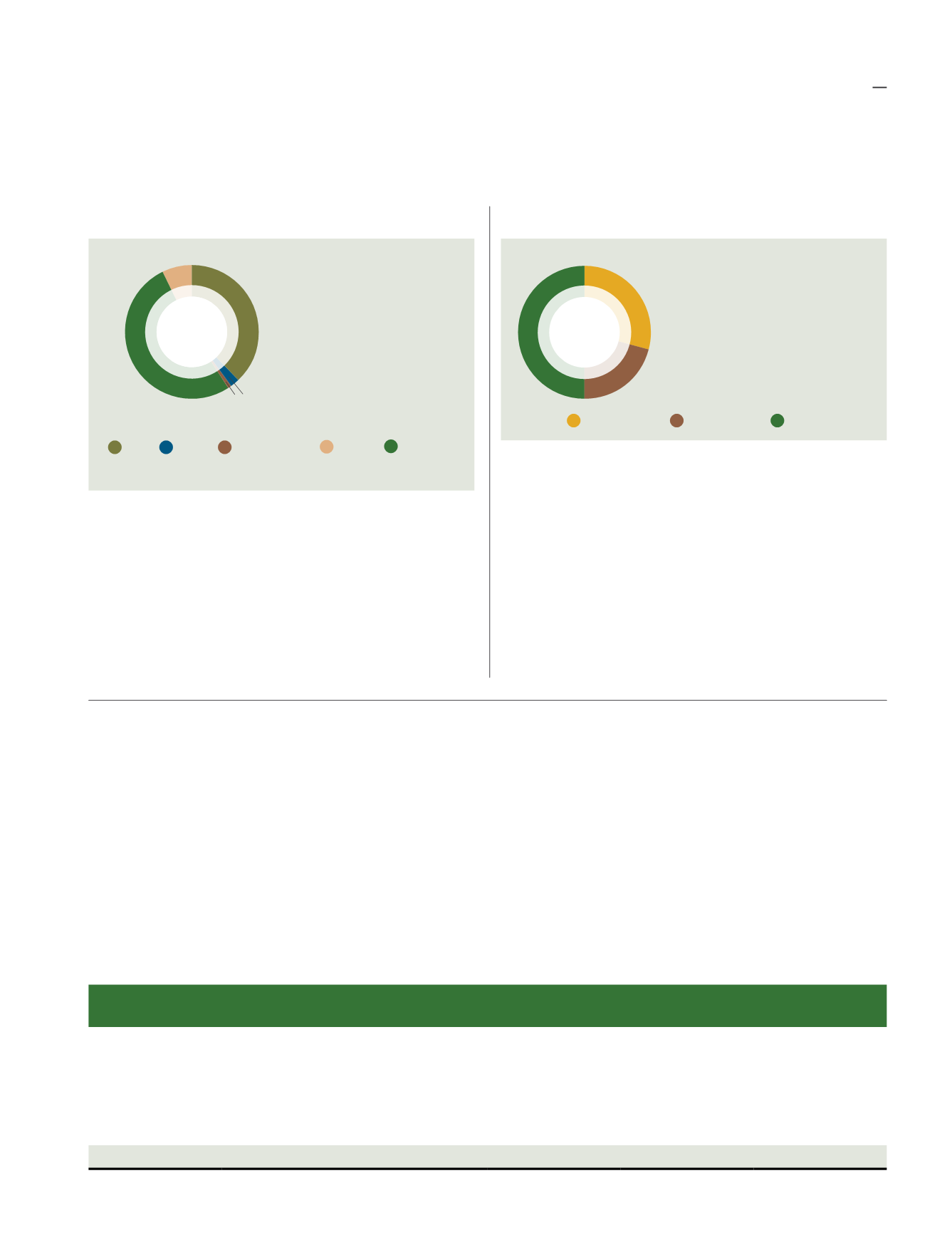

Water Consumption

Breakdown of Water Consumption by Division (m

3

)

839,941.76

m

3

Total water consumed by the Group

(FYE2018: 734,432.00 m

3

)

Plantation

Bulking

Head

Office

Building

Food

Manufacturing

The increase in water consumption in IFC was a result of

a couple of factors, the first of which is due to an increase

in IFC’s total fish production by 28%, on the back of

improved demand for mackerel in the PNG market. This, in

turn, led to IFC procuring more mackerel from its suppliers

and this includes purchasing frozen-on-deck mackerel.

These frozen-on-deck mackerel requires thawing which

involves higher water usage. We recognize the need for

reducing our water consumption and will strive to do so

through greater efficiency and water management.

38%

7%

2% 1%

52%

50%

21%

29%

environment

41