Kumpulan Fima Berhad

(11817-V)

62

EMERGENCY PREPAREDNESS

Emergency preparedness is an important

aspect within our operations, thus our

facilities are equipped with firefighting

systems and have in place adequate

responseplans, spill prevention andother

programs to respond to emergencies.

INCIDENT FREQUENCY RATE

Frequency Rate is recorded based

on number of lost time injuries “LTI”

occurring in the work place for every

1 million man-hours worked. During

FYE2017, the Group recorded Lost

Time Frequency Rate (“LTIFR”) of 12.35

(FYE2016: 10.21) based on the following

formula:

LTIFR =

No. of accident

Total man-hours

worked

X 1 mil

OCCUPATIONAL SAFETY &

HEALTH

We regard safeguarding of our

employees, neighbours, visitors and

assets as a core indicator of our business

success.

Towards this end, we comply with all

the relevant national laws, regulations

and other requirements relating to best

practices in occupational safety and

health; and constantly carry out activities

aimed at preventing work injuries.

Preventive and scheduled maintenance

are regularly performed on all the

Group’s facilities, plants, storage tanks

and terminals; whereupon repairs and

replacements are made when necessary

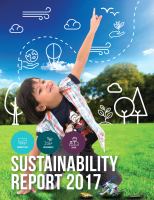

or appropriate. Employees who use any

machinery are trained to do so properly,

while training programmes in the use

of personal protective equipment

for workers handling or exposed to

hazardous materials are regularly

conducted and have been, and will

continue to be, a vital part of the Group’s

operations.

All divisions have health and safety

committees which consist of divisional

management and employees. It is to

these committees that incidences are

reported, and where compliance to

policies is monitored and improvements

are discussed.

For the second consecutive year,

Fimachem Sdn Bhd was presented with

Merit Awards in the Employee Health

and Safety Code and Distribution Code

categories at the Chemical Industries

Council of Malaysia Responsible Care

Awards 2016/17. During the year,

PTNJL’s palm oil mill was accredited

with

Sistem Manajemen Keselamatan

dan Kesehatan Kerja (or “SMK3”)

a

local Indonesian Government safety

certification that is comparable with the

globally recognized OHSAS 18001: 2007.

SAFETY COUNTS

920

days

ZERO

fatality

without lost time

incident achieved

by PKN as at 31

March 2017

recorded by all divisions in FYE2017.

SUSTAINABILITY

REPORT 2017

Chemical Industries

Council of Malaysia