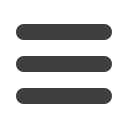

FYE2019

FYE2020

Total Injuries by Type

10

11

Falling Objects

4

5

Physical

15

3

Tools

being absent from work for more than 5 working days will be

considered ‘a lost time injury’.

LTIFR corresponds to the number of lost time injuries

occurring in the workplace per 1 million hours worked.

During the previous reporting year, the Group recorded

an overall LTIFR of 2.77 incidents per million hours worked

against LTFIR of 4.39 recorded in the previous year. The

indicator helps us to track the effectiveness of measures

taken to improve safety and health performance in all

business divisions. In addition, it helps the group to identify

the most useful preventive action.

The Group reported 2.77 LTIFR for every 1 million man-hours

worked. Some of the accidents arising from the Plantation

division include injuries caused from the usage of work tools

such as machetes and sickles. Others have falling fronds,

thorn cuts and injuries due to the handling of FFB.

Covid-19 Response

The Group has taken extensive measures across our

businesses to safeguard employees and customers from

the Covid-19 pandemic. We have implemented additional

employee safety measures based on guidance from the

relevant health authorities across all our premises, including

enhanced hygiene protocols, social distancing, mask use

and temperature screenings.

We enhanced daily sanitation practices in all our premises.

We have installed hand sanitisers across all our premises,

added signs and floor decals to promote physical distancing.

Workstations have also been evaluated for adherence to

physical distancing guidelines. As at the date of this Report, all

of our businesses are operating without significant disruption.

In our Manufacturing and Bulking Divisions, for instance,

all chemical related product supplied are issued a Safety

Data Sheet (“SDS”). This sheet clearly indicates the type of

chemical that employees are being exposed to and how

best to handle them. The SDS will indicate the potency of

the chemical and the level of danger it may pose to the

employee i.e. mild, moderate, highly dangerous. The safety

measures taken by the employee will commensurate with

the danger level.

Manufacturing Division

has achieved 2,015 days (which is

equivalent to 5.5 years) without any lost time incident as at

31 March 2020. During the year in our Plantation Division,

PTNJL’s palm oil mill has retained its accreditation of

Sistem Manajemen Keselamatan dan Kesehatan Kerja (or

“SMK3”), a local Indonesian Government safety certification

that is comparable with the globally recognised OHSAS

18001:2007.

Tragically we suffered two fatalities in FYE2020. In April 2019,

an estate worker in Ladang Amgreen, Sarawak was fatally

injured a while attending to equipment repairs. In October

2019 an employee at our PTNJL oil mill was fatally injured

while trying to remove some dirt near the mechanical nut

stirrer. As a company standard, we offered support to the

bereaved families and conducted investigations. These

incidents had served to remind us that we must continue

to strive to make our workplaces safer and our employees

cognisant of the risks in their respective job functions.

Lost Time Injury

Beginning FYE2020, we have applied the methodology

of the Malaysian Department of Occupational Safety and

Health on the Lost Time Injury in computing our Lost Time

Injury Frequency Rate (“LTIFR”). The methodology stipulates

that injuries incurred by our employees resulting in them

Sustainability : Social

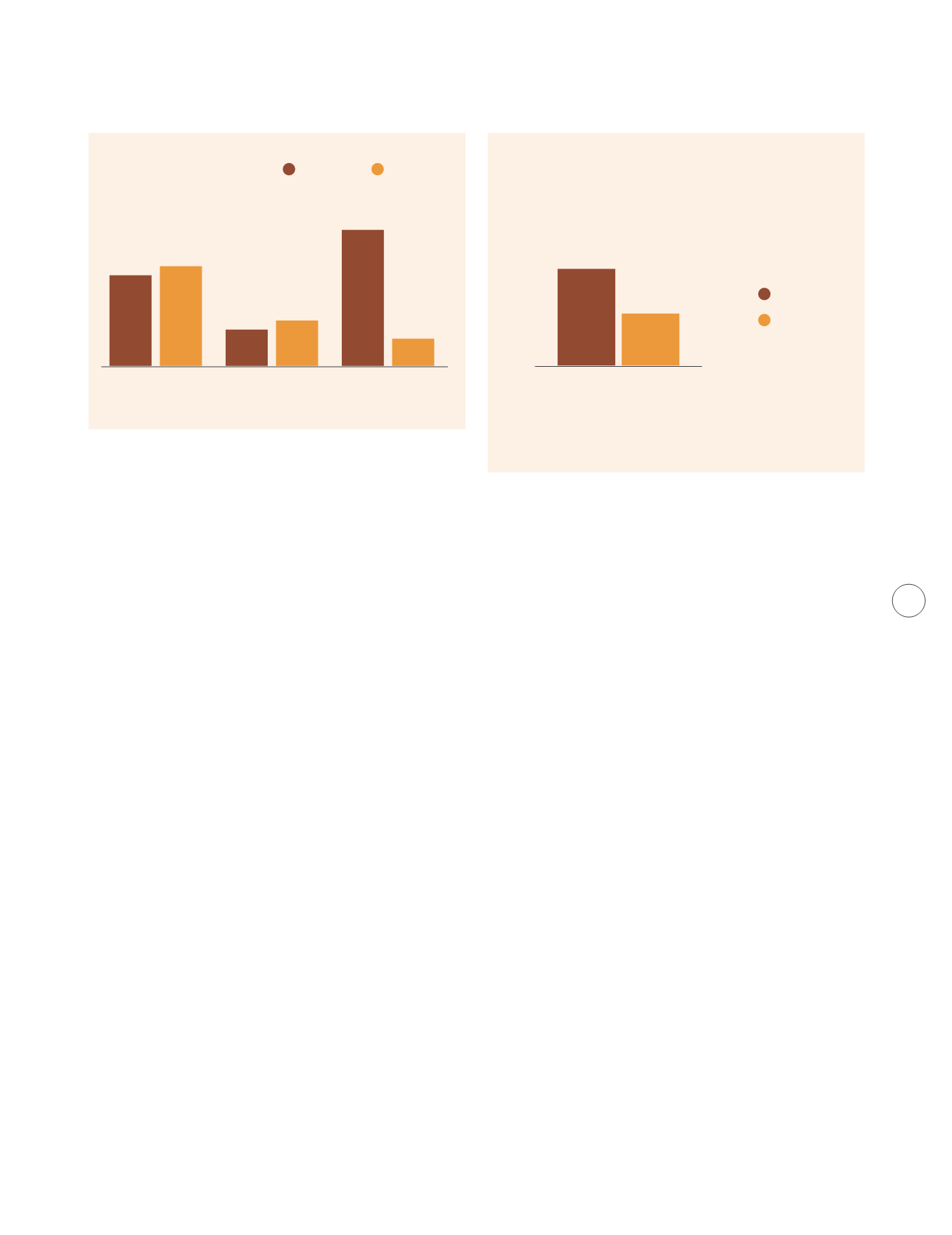

FYE2019

FYE2020

Lost Time Injury Frequency Rate

(Per 1 Million Hours Worked)

*4.39

*2.77

FYE2020

FYE2019

* Note: Adjusted to be in line with the methodology of the Malaysian

Department of Occupational Safety and Health.

kumpulan Fima Berhad

(197201000167)(11817-V)

Annual Report 2020

75