Environmental Assessment

During the year, we have successfully fulfilled the relevant

EIA criteria and obtained the permissions and approvals

necessary to commence development at our greenfield

estate in Sg. Siput, Perak measuring 2,000 hectares. Implicit

in these approvals is the requirement to abide by riparian

buffer zones, water catchment and forest conservation areas.

Mechanisation of Field Operations

The Group has taken actions to increase the level of

mechanisation within our oil palm plantation operations,

particularly for in-field collection and application of fertiliser.

As part of our estate planning process, infrastructure at all

our new developments are designed to facilitate in-field

mechanisation. Mechanisation improves efficiency and

worker safety. It also reduces cost and dependency on

manual labour. Our pineapple plantation in Ayer Hitam,

Johor, have fully mechanised their plastic mulching and

fertiliser applications during the land preparation exercises

which allows for greater efficiency of labour and fertiliser use.

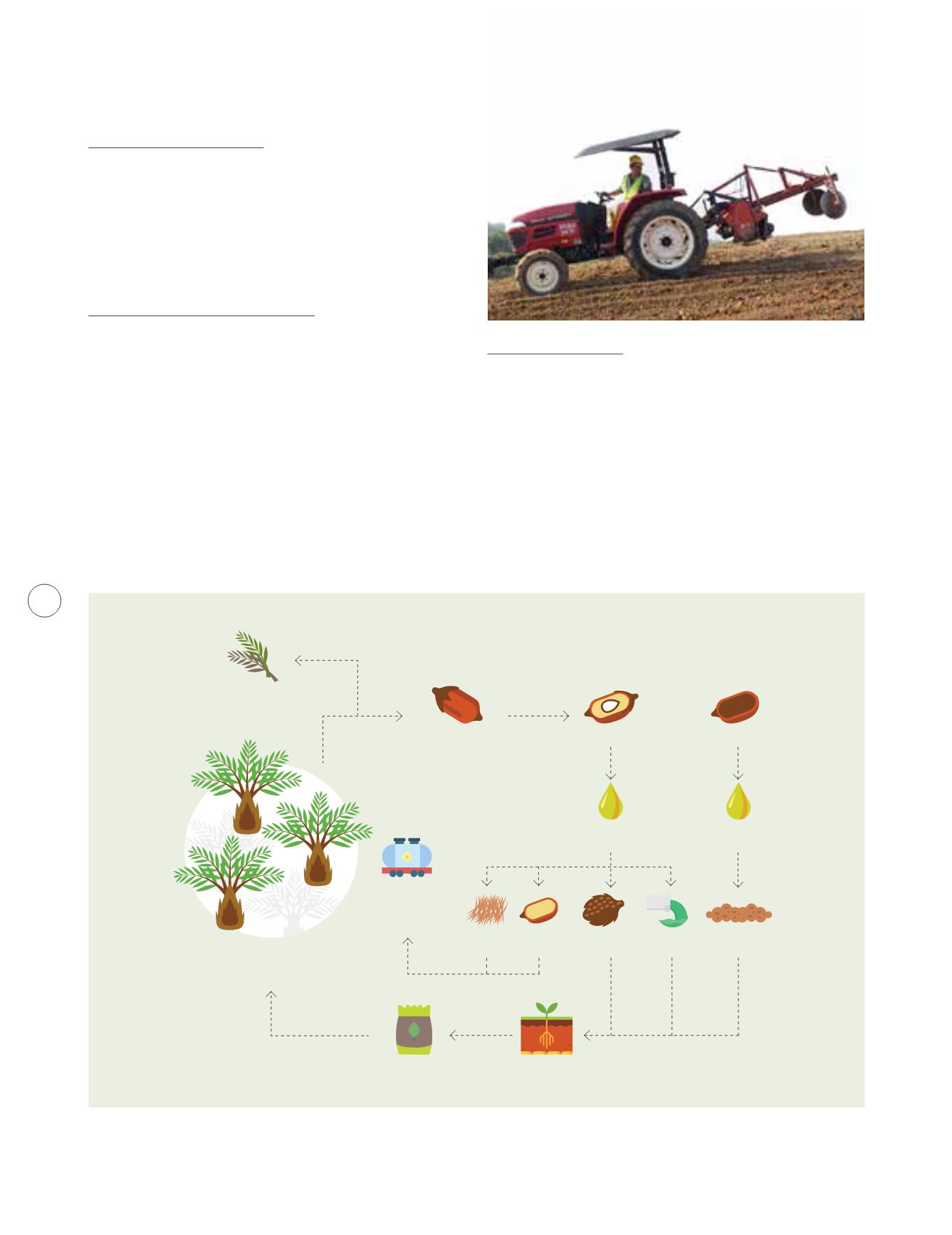

Kernel

Mesocarp

Compost

Organic Fertiliser

Mulch

Old stems & leaves

are made into mulch

Shell

Fibre

Empty Fruit

Bunch

POME Palm Kernel

Cake

Crude Palm Oil

Crude Palm

Kernel Oil

Palm fruit is harvested from

oil palm trees in the form

of fresh fruit bunches

Fresh Fruit

Bunch are sent

to the mill within

24 hours

By-products

Fuel Fibre & shells

are used as boiler

fuel in the mills

Sustainability : Environment

Waste Management

The

Plantation Division

adheres to a zero-discharge policy

by recycling waste and by-products. At our palm oil mill in

Indonesia, oil mill waste comprises of POME and EFB. These

are both utilised in various ways:

POME discharged from the mill must not be reintroduced

into the environment in its raw form. Raw POME has a

high acid content and, due to its rich nutrient content, the

Biological Oxygen Demand (“BOD”) level is high. However,

Annual Report 2020

kumpulan Fima Berhad

(197201000167)(11817-V)

62